The heart of every low-voltage landscape lighting system is the transformer. They are critical to a working outdoor lighting system as it transforms the 120 volts at the outlet to lower voltage that the landscape lights can use. Inside the transformer the wire windings reduce the incoming electricity of 120 volts down to 12 volts — a 10:1 ratio. If a low-voltage fixture comes in contact with 120 volts it will be promptly destroyed.

Transformers come in all sorts of finishes, sizes, wattage and voltage range. In the past, before the advent of LED, we used transformers with a wide range of voltage options. We have installed transformers from 150 watts to as many as 1,500 watts. 1,500-watt transformers are large, heavy and expensive. These were used if we had a large job with lots of quartz halogen landscape lights.

One of the differences between the do-it-yourself transformers you find at the big box stores and ones used by professionals is that the professional transformer has a multi-tap feature. A DIY transformer typically has only a 12-volt lead to connect a wire. A professional transformer has several voltage choices or multi-tap.

Most professional transformers offer voltage choices of 12 to 15 volts. The higher voltage choices are very important when light fixtures are further away from the transformer. If the voltage at an LED fixture is too low, it will not work or flicker. Neither will create a beautiful night-time look on a home.

If the fixtures are far from the transformer, you may need to use a transformer that has a higher voltage option. Some will have voltage options from 12 to 22 volts. This will help to overcome the challenge of voltage drop.

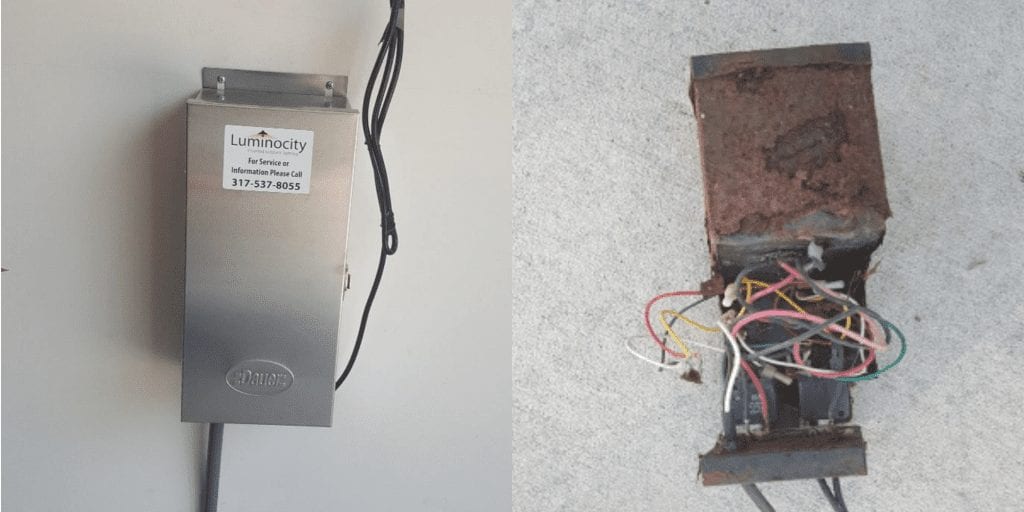

Transformers at the big box stores are typically made of steel and painted black. Steel will rust and over time can fail. Professional grade transformers are generally made of stainless steel. Stainless steel not only looks good but also will last much longer than those that are painted steel. Stainless steel will withstand the elements well. Here you can see an example of a black rusty transformer we recently replaced.

DIY transformers are cheap not only in price but also in quality. Transformers are either laminated or toroidal. A toroidal transformer consists of a ring-shaped (torus) ferromagnetic core, around which both primary and secondary copper coils are wound. Laminated windings inside the transformer are less efficient.

Laminated core transformers have an insulated lamination, which means the transformer will be hotter, can be noisy and are more prone to failure. Toroidal transformers have wires that are wound around a donut and then embedded in epoxy. This results in a cooler operating transformer and more efficient operation.

Professional grade transformers are generally about the size of a shoe box. Most transformers have a door in the front that opens. Inside there is an outlet that accommodates a timer.

When installing a transformer, it should be mounted well above the ground. According to the National Electrical Code (NEC) the base of the transformer is to be at least 12 inches above the ground. This helps to keep moisture from contacting the electrical components. Electricity and moisture don’t go well together!

The hallmark of a professionally-installed transformer is that it is level to the ground and the conduit is securely affixed to the base. This not only looks tidy but also helps to maintain a dry environment inside the transformer.

You may have wondered why professional-grade transformers cost more than the ones you can find at stores. Now you know!